The medical possibilities seem to be almost unlimited in western countries today: Preventive treatments, a multitude of effective drugs, complicated operations, organ transplants and artificial insemination have become an integral part of the repertoire.

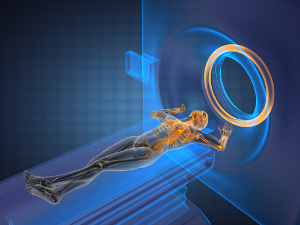

Our focus in medical technology is to support the development services of technologically highly complex devices. In particular, these are X-ray systems, radiotherapy equipment and ultrasound systems, which are major engineering challenges due to their complex combinations of electronics, control system and mechanics.

Constantly evolving requirements, such as the reduction of emission limits or the requirements of the German MedGV (national) and FDA (international), require continuous further training for our engineers. This is a prerequisite for using knowledge with a high sense of responsibility in the sustainable development of new products for medical technology.

Working on constructive topics in device development:

- Creating assemblies and drawing derivations with mediated knowledge in 3D modelling

- Creating production documents for manufacturing individual parts

- Preparing assembly and individual parts drawings and part lists

- Integration of CAD components in the I-DEAS 3D development environment

- Comparing interfaces

- Implementing manufacturing knowledge in plastics and sheet metal processing

2. Collaboration in developing and designing a transmission control system for a surgical patient table:

- Selection, testing and evaluation of materials and geometries for suitability for use and resistance (with regard to temperature, vibration, tightness, medium oil, etc.)

- Optimising the product design from the sample phase to series production

- Creating drawings and specifications

- Interface function to external suppliers

- Analysis of qualification patterns

- Construction and procurement of measuring equipment (workpiece holders, gauges, etc.)

3. Performing strength tests on a high-precision CT flap:

3. Performing strength tests on a high-precision CT flap:

- Development of the test method

- Construction and adaptation of corresponding fixture parts

- Stiffness analysis of the support and base frame of the table in 3 directions with 2 geometry variants

- Assessment of manufacturing, geometry and material variants

- Optimisation of the test methods