Electrical engineering

Automotive Engineering

Automotive Engineering is one of the core competencies of our service portfolio.

We are active across the entire value chain, from the conceptual idea to the finished product, both for OEMs and suppliers.

In particular, we specialize in the fields of body, interior, chassis, and drivetrains.

In hardware development, we support our clients with the following services:

- Overall project planning and coordination

- Creation and analysis of specifications and requirements

- Hardware development in the field of analog and digital circuit design using CAE tools for control units

- Design of circuit concepts and designs using different PCB techniques for circuit development and calculation

- Qualification and development of simulators for control units

- Monitoring and coordination of hardware prototype construction, as well as testing and validation of hardware through appropriate methods and documentation

- EMC measurement and subsequent optimization

- Integration of individual components and modules into the overall system

- Documentation of the entire project execution using word processing and CASE tools

- Coordination of various departments such as production and quality planning, procurement, software development, and logistics

In software development, we support our clients with the following services:

- Overall project planning and coordination

- Analysis and specification of required software

- Creation and analysis of specifications and requirements

- Development and implementation of system and functional software

- Conducting tests and measurements using modern simulation tools, documenting them, and subsequent verification of the existing software

- Automation of tests to be performed

- Integration of individual software components or modules into the overall system

- Documentation of the entire project execution, from development to acceptance

- Coordination of various departments such as production and quality planning, procurement, hardware development, and logistics

Concrete project examples from automotive technology:

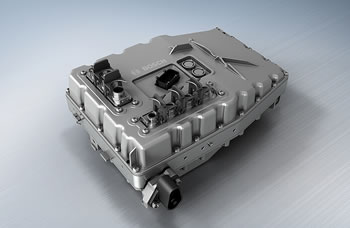

- Hardware development in the field of hybrid drivetrains – power electronics for controlling energy flows in hybrid and electric vehicles: Validation and tolerance calculations for circuit modules (analog, digital, power electronics), measurement and verification, commissioning in HV laboratory, processing of project-specific FMEA points, documentation in DOORs, adaptation of circuit modules

- Hardware development of battery management systems for controlling lithium-ion cells: Performing validation and verification measurements, troubleshooting and analysis on the battery pack, development of a switchbox for test automation

- Software development for DCU control units: Creating overall software for an interface microcontroller for multiple variants of a DCU control unit with integrated inertial sensors, testing and verifying software in the overall system context

- Testing and trial of synchronous motors for steering systems: Setup and preparation of tests according to customer specifications and products, adaptation and programming of measurement equipment, monitoring the execution of tests, analysis and data processing, analysis of acoustic data and measurements, evaluation and creation of technical reports, testing and release of prototypes before customer delivery, data processing, creation of reports

- Pre-development of longitudinal dynamics for hybrid vehicles: Function development, operational strategy for brake energy recovery, control of an electric add-on vacuum pump, communication/interface definition, stability monitoring, specifications for suppliers, supervision of test vehicles and their setup and equipment programs, monitoring parts procurement and installation, coordination of modifications (ECU, HCU, brake devices, foot pedal system …), testing and evaluation of software versions, creation of test catalog for validation, application of functions in test vehicles, commissioning of concept system prototypes, commissioning of developed software versions, validation based on the created test catalog, documentation, and final presentation

- Project planning and implementation of changes to the body controller SMART for the car-sharing innovation car2go: Clarification of project requirements, creation of a requirements specification, clarification of changes with the supplier, commissioning of changes, creation of test cases for control unit tests according to requirements, component testing in the lab and vehicle, creation of test documentation, troubleshooting of urgent vehicle issues, execution of necessary software updates, release tests of the software, and documentation