In these times of globalisation, automation technology is indispensable for increasing productivity and competitiveness. Quality, costs and time are essential factors in rationalising almost all processes. For machine manufacturers and system operators, it is crucial to reduce the time from the idea to the finished product to a minimum with maximum flexibility.

In these times of globalisation, automation technology is indispensable for increasing productivity and competitiveness. Quality, costs and time are essential factors in rationalising almost all processes. For machine manufacturers and system operators, it is crucial to reduce the time from the idea to the finished product to a minimum with maximum flexibility.

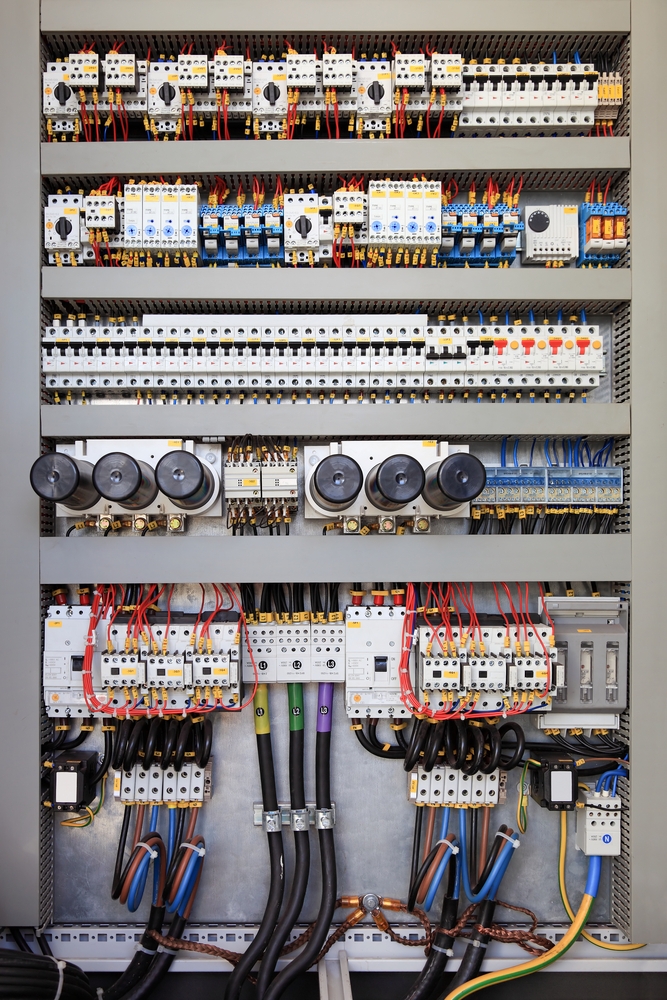

We have acquired extensive know-how through several years of involvement in automation technology. Our main focus is on automation technology, drive and control technology, process visualisation and measurement data acquisition, especially in the processing industry and in special machine construction.

Automation technology is important for almost all processes we deal with today: These are integrated, for example, in production engineering, robotics, automotive engineering, the control systems of machines in industry and at home. Measurement and automation technology solutions especially enable the aspects of safety, environmental protection and resource conservation, as well as product intelligence and usability within processes.

Since we are fundamentally not bound to any particular make of equipment, we can operate various PLC systems.

Range of project planning services:

In the field of project planning, we are happy to assist you in the following areas:

- Design and implementation of the objective

- Specification of the mechanical structure of module racks

- Layout of electrical calculations

- Creation of parts lists, as well as measurement and type test protocols

- Preparation, evaluation and documentation of data for order processing

Range of electrical construction services:

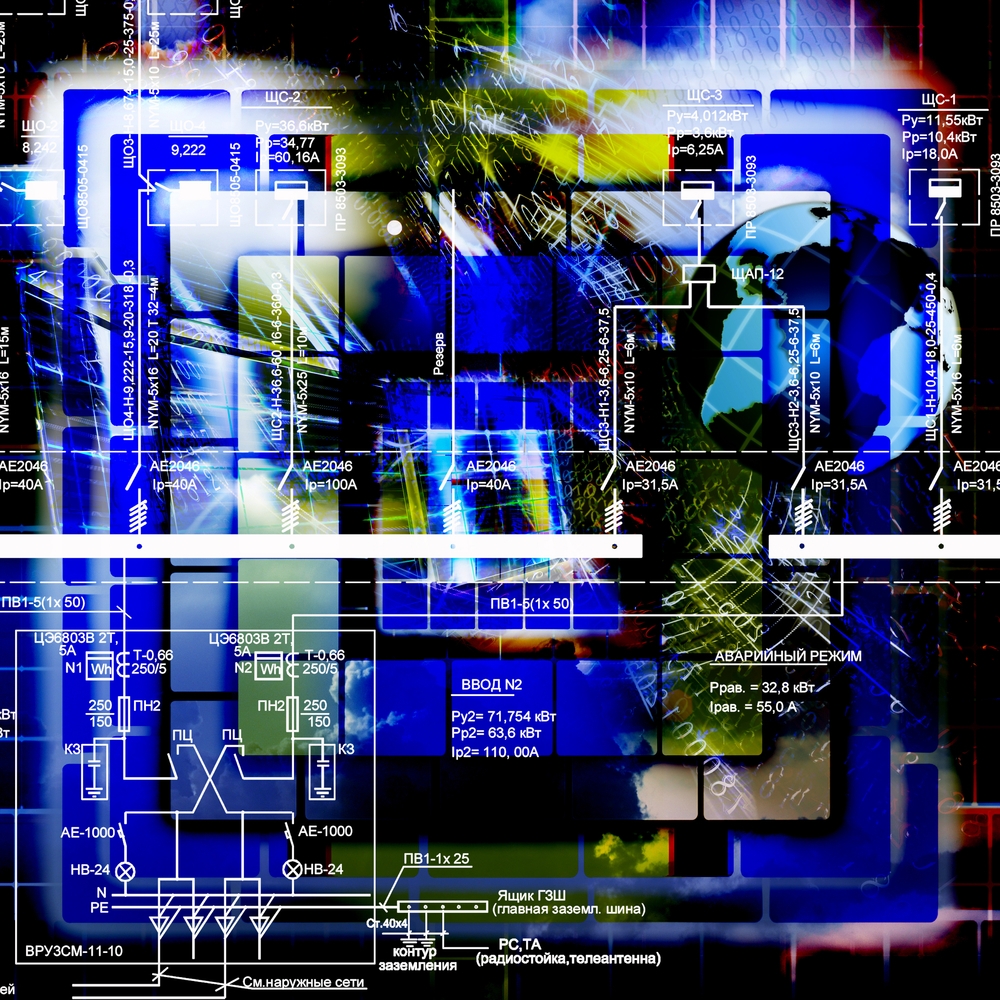

We use the following CAE systems for electrical design:

- EPLAN

- ELCAD

- WSCAD

Programming:

A wide variety of hardware is used to implement your optimum control system. By using different parametrisation and programming languages, as well as the most modern software tools we create:

A wide variety of hardware is used to implement your optimum control system. By using different parametrisation and programming languages, as well as the most modern software tools we create:

- PLC controllers e.g. based on the S5 or S7 family from Siemens

- CNC controllers of the SINUMERIK family from Siemens

- Control systems with state-of-the-art drive systems such as MotionControl, CAN-/Profi- or Interbus

- Conventional small control systems

- Pro Tool/Pro, COROS/LSB, WinCC

Range of commissioning services:

We offer you support for planning and project engineering your systems. Together with you, we create a specification sheet, plan and follow the project in terms of hardware and software. Our experienced project engineers accompany you through the entire project planning phase. Use our experience to successfully implement your automation solution.

Concrete case studies of services within automation technology:

- Independent commissioning, troubleshooting and repairs to SIMOVERT MV

- Commissioning of SINAMICS low voltage converters

- SIMOVERT ML2 medium-voltage converters

- Implementation of worldwide commissioning and de-escalation operations

- Description of the software requirements

- Creation of the software requirement specification sheet for the time-controlled bus system of a PLC with 12 signal modules

- Description of the TTCAN system matrix, master and slave software architecture, and interface for PROFINET

- Creation of sequence diagrams and state machines from the TTCAN protocol using the “Visio” program

- CAN bus programming

- Programming a TTCAN system matrix for 12 signal modules with the “IAR Compiler” for ARM microcontrollers

- Using the CANalyzer analysis tool for CAN messages

- Internal order processing

- Technical clarification of orders

- Creation and revision of material parts lists, documentation, layout plans and dimensional drawings, system-specific data sheets, circuit diagrams

- Coordination of production and test facility

- Support for internal customers and suppliers

Inspection of testing and processing facilities for optimisation approaches, preparation and realisation of improvements on the basis of planning, evaluating economic efficiency, product quality, technical innovation and availability:

- Recording, processing, evaluating and eliminating control engineering problems for relevant fields

- Preparation of decision bases and presentation of alternative solutions with regard to technical execution, costs, reliability, process safety and environmental influences

- Evaluation of the individual possible solutions, coordination of these with the affected bodies and preparation of recommendations for decisions

- Participation in project teams by developing, evaluating and implementing testing and processing facilities

- Creation of requirement profiles, technical implementation specifications and evaluation of alternative designs proposed by the tendering parties

- Creation of functional specification sheets or service specifications

- Preparation of project schedules and coordination with related parties

- Monitoring of deadlines, the quality of execution, technical function and compliance with regulations during implementation

- Implementation and management of sub-project coordination of overall projects

- Assumption of the responsible, legal coordination function in compliance with the German Accident Prevention Regulations (UVV) for the transferred projects

- Commissioning systems, ensuring production capability and carrying out acceptance tests with the involvement of all affected specialist departments

- Preparing acceptance protocols and arranging for faults and complaints to be resolved

- Assisting with maintenance and resolving complicated faults in systems

- Preparation of documentation and system manuals

- Responsibly taking measures to safeguard production on systems during production-free periods

- Supervision of the production start-up process